Cipher Neutron is a pioneering force in the clean energy transition, dedicated to driving innovation and sustainability in green hydrogen production, power generation, and energy storage solutions. Formed to accelerate the global shift towards renewable energy, Cipher Neutron leverages advanced technologies to develop economically viable and environmentally friendly solutions. Our highly efficient AEM Electrolysers help reduce the cost of green hydrogen production, meeting global government targets. These AEM electrolysers produce hydrogen without reliance on iridium and are PFAS-free, ensuring sustainability and overcoming significant supply chain constraints. Additionally, our groundbreaking Reversible Fuel Cells not only generate electricity from hydrogen but also efficiently store energy using a proprietary Graphene slurry. This versatile technology provides a robust alternative to traditional battery storage, reducing maintenance costs and enhancing energy efficiency. At Cipher Neutron, we are committed to leading the clean energy revolution, ensuring a sustainable and prosperous future for all.

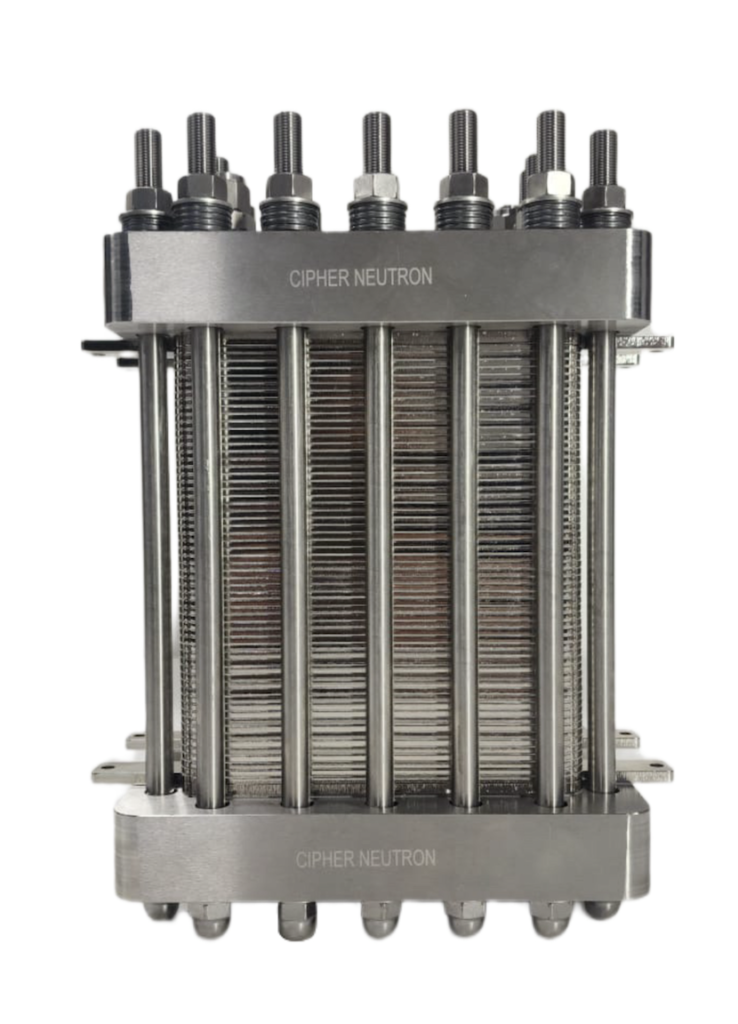

Discover the cutting-edge technology in water electrolysis: Anion Exchange Membrane (AEM) electrolysis. This advanced method excels in efficiently separating water into hydrogen and oxygen gases. By seamlessly combining the advantages of both Alkaline and Proton Exchange Membrane (PEM) electrolysis, AEM electrolysis emerges as a highly efficient and cost-effective solution for green hydrogen production, promoting sustainability.

Our AEM Electrolysers boast over 90% efficiency at the stack level based on Higher Heating Value (HHV) metrics, coupled with a high ampacity rating of 1 amp per cm². This unparalleled efficiency not only ensures high hydrogen production rates but also significantly drives down the cost of hydrogen. The high efficiency, combined with cost-effectiveness and sustainability, positions AEM electrolysis as a premier choice for green hydrogen production.

The compact, scalable design of AEM Electrolysers makes them ideal for projects of all sizes, from small-scale installations to large industrial applications. Their ability to produce highly pure and pressurized hydrogen gas translates to lower capital and operating expenditures, establishing them as one of the most cost-effective and sustainable electrolyser technologies available today.

In addition to their high efficiency and sustainability, AEM Electrolysers contribute to prolonged electrolyser lifespan, minimizing the need for repairs and reducing overall process costs. This makes them an excellent investment for any green hydrogen project.

Embrace the future of green hydrogen production with Cipher Neutron's innovative AEM electrolysis technology. Experience unmatched efficiency, sustainability, and cost-effectiveness in your hydrogen production projects with AEM Electrolysers. Join us in leading the way to a cleaner, greener energy future.

Cipher Neutron is a trailblazer in Precious and Scarce Metals-Free green hydrogen technology, leading the charge toward a sustainable and eco-friendly future. In a global landscape where a significant portion of precious and scarce metals, such as iridium, are concentrated in regions like South Africa, Cipher Neutron's pioneering approach marks a seismic shift in the hydrogen production paradigm.

By avoiding the traditional dependence on precious and scarce metals, Cipher Neutron revolutionizes green hydrogen technology with an ingenious fusion of alternative materials and cutting-edge AEM Electrolysers. This groundbreaking methodology not only reduces the environmental impact of conventional methods but also addresses the high costs associated with using precious metals.

Through the adept application of advanced materials and state-of-the-art AEM technology, Cipher Neutron has engineered a sustainable solution for green hydrogen production. This innovative approach enhances cost-effectiveness and underscores the company's unwavering commitment to fostering a cleaner, more sustainable future.

By embracing forward-thinking technologies and methodologies, Cipher Neutron significantly contributes to global efforts to create a greener world. With our highly efficient AEM Electrolysers, we are driving down the cost of green hydrogen production, making it more accessible and aligned with global government targets for sustainable energy.

Per- and polyfluoroalkyl substances (PFAS), colloquially known as "forever chemicals," have historically played a pivotal role in traditional Proton Exchange Membrane (PEM) Electrolysers. However, the alarming association between PFAS and potential health risks, highlighted by the Agency for Toxic Substances and Disease Registry, has cast a shadow over their widespread use. These risks include an elevated susceptibility to kidney failure and cancer, diminished fertility in women, and adverse impacts on the growth and learning abilities of children.

In response to growing global apprehensions surrounding PFAS, various governments, including the European Union, are deliberating the prohibition of specific PFAS, reshaping the dynamics of the supply chain for electrolysers. Amidst this evolving landscape, Cipher Neutron stands out with a proactive and forward-thinking approach. The company pioneers the use of Anion Exchange Membranes entirely composed of PFAS-free materials in their AEM Electrolysers. This unwavering commitment signifies a crucial stride toward the development of sustainable and environmentally friendly electrolysers.

By steering clear of PFAS and prioritizing alternative, eco-friendly materials, Cipher Neutron addresses the health and regulatory challenges linked to the conventional use of PFAS. This strategic decision positions Cipher Neutron at the forefront of the eco-friendly electrolysis frontier, contributing significantly to a cleaner and safer future. By aligning with emerging regulatory standards and championing a paradigm shift towards sustainable and health-conscious electrolysis practices, Cipher Neutron leads the way in advancing AEM Electrolyser technology.

Chemical Industry

Oil and gas Industry

Mining Industry

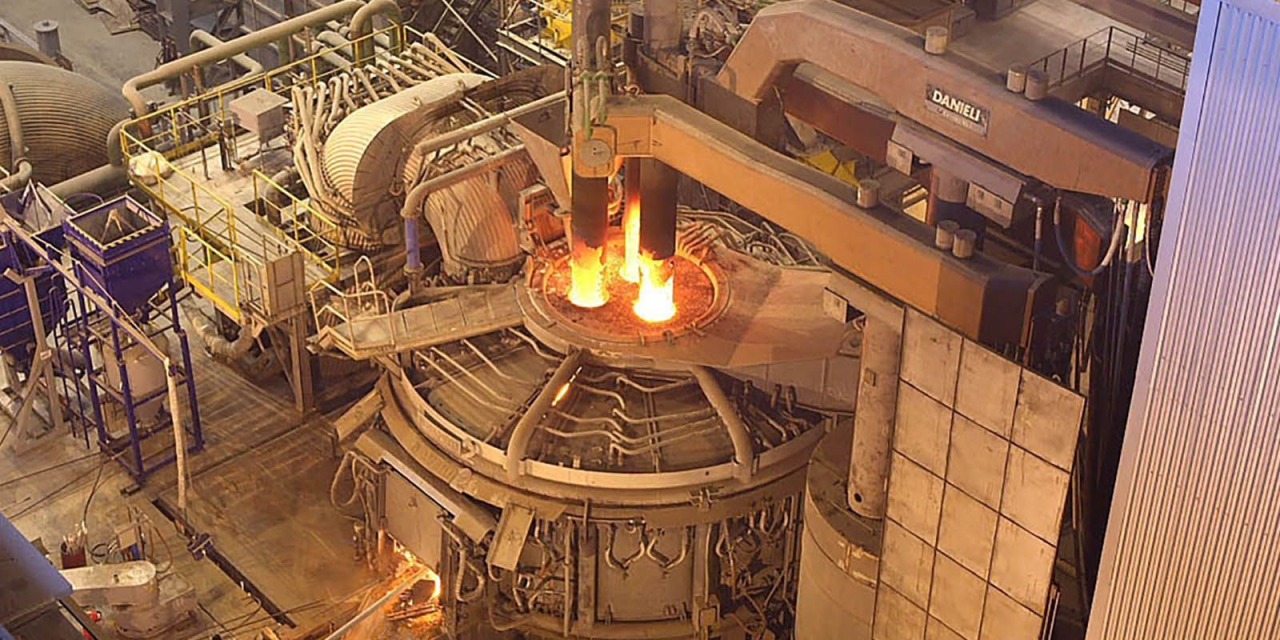

Steel Industry

Transportation Industry

Since its inception, Cipher Neutron has consistently positioned itself as a pioneer in the transformation of the global green energy technology landscape. The company's unwavering commitment to innovation is vividly demonstrated through its groundbreaking and patent-pending Reversible Fuel Cell (RFC), a technological marvel that ingeniously harnesses Graphene Slurry for the non-compressed storage of green hydrogen. This pioneering technology has the potential to revolutionize our conventional approach to energy production and storage, offering an environment-friendly and effective alternative to traditional compressed hydrogen storage methods.

The RFC developed by Cipher Neutron stands as a unique and comprehensive system, capable of both producing green hydrogen as an electrolyser and generating clean electricity as a fuel cell. Often referred to as the "Hydrogen battery," the reversible fuel cell serves as a testament to the company's innovative spirit, providing a versatile and dynamic solution to meet the evolving demands of the energy industry.

This dynamic reversible fuel cell seamlessly transitions between two modes – E-Mode, functioning as an electrolyser for hydrogen generation, and FC-Mode, operating as a fuel cell for power generation. The integration of Graphene for non-compressed energy storage further enhances the adaptability and efficiency of this groundbreaking technology.

In a bold move, Cipher Neutron aims to lead the industry by becoming the first company to commercially offer reversible fuel cells for both residential and industrial applications. This visionary approach signifies a significant leap towards a more sustainable and accessible energy future, showcasing Cipher Neutron's commitment to democratizing transformative technologies and making a tangible impact on global energy landscapes. Through the incorporation of Graphene and the innovative design of the reversible fuel cell, Cipher Neutron sets the stage for a new era in green energy technology, marked by versatility, efficiency, and environmental responsibility.

Cipher Neutron's Reversible Fuel Cell is:

Clean Energy Storage

Residential Backup Power

Cottages/Remote Communities

The strategic investment by dynaCERT Inc. in Cipher Neutron is meticulously crafted to spearhead the integration of AEM electrolysers into the global market. This partnership marks a significant step forward in advancing clean energy solutions and underscores the myriad benefits of establishing a production line capable of manufacturing AEM electrolysers. dynaCERT's financial commitment and confidence in the innovative potential of AEM technology highlight the strength of this investment.

A key advantage is the semi-automated production line in Toronto, designed to ramp up production to meet the needs of hundreds of big and small projects. With the capacity to manufacture 100 MW of AEM electrolysers on a yearly basis, this facility ensures a seamless and efficient supply chain. This production capability is crucial during the transitional period until Cipher Neutron's dedicated AEM production facility becomes fully operational, enabling a rapid response to market demands and scalability for various project sizes. Cipher Neutron is now expanding to increase its capacity to 1 GW by the end of 2025 to meet global demand.

The streamlined production line is expected to attract significant interest from major players in the energy sector, potentially leading to substantial sales and partnerships. By offering a reliable and scalable solution, Cipher Neutron positions itself to meet the growing demand for AEM electrolysers, driving the adoption of green hydrogen technology on a global scale.

Additionally, the initiative is poised to create job opportunities, foster economic growth, and contribute to the advancement of sustainable technologies. The establishment of an efficient and scalable production line positions Cipher Neutron to capitalize on the increasing interest in green hydrogen, ensuring it plays a pivotal role in the clean energy transition.

Read More

Read More

Read More

Read More

…

Read More

Read More

Read More

Read More

Read More

…

Read More

…

Read More